Combined drawing systems

Double pay-off

The double pay-off ensures faster feeding of the starting material. Each of the two crowns can be hydraulically tilted and refitted during operation.

The fixed base frame has a powered turning device. The carousel frame is equipped with integrated hydraulics and tilt cylinders. The pay-off is either controlled by a separate cabinet or is controlled by the control cabinet of the drawing machine. In addition to the foundationless version shown above, there is also a stronger version, which is used in particular for large diameters. This requires a foundation.

Coil opening robot

The coil opening robot feeds the leading end of the coil into the prestraightener.

The fixed base frame has a driven turning device. The coil opening robot can perform any movement by the operator using joysticks, so that it is possible to open the start of the wire without manual intervention. In addition to the coil opening robot shown above, there is also the classic “RIBI” version.

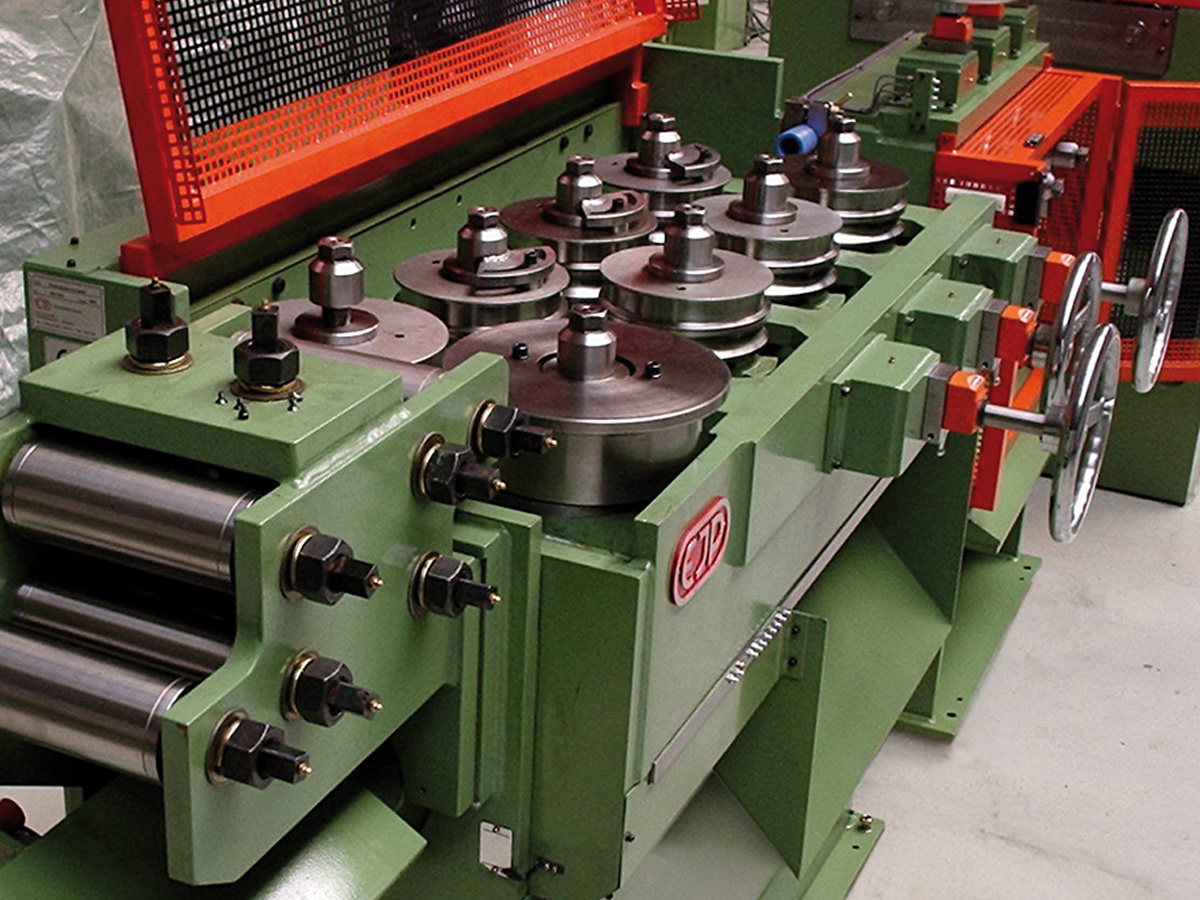

Prestraightener

The prestraightener ensures optimum preparation for the subsequent processes.

The driven horizontal pre-straightener is important for the strong deflection against the winding direction of the wire ring. It is followed by the vertical, non-driven pre-straightener. Depending on the version, the rollers are adjusted manually or by motor, but are always displayed digitally. In order to enable a quick changeover of the machines, the pre-straightener has double rollers per shaft, so that changing the rollers is unnecessary.

Shotblasting machine

The shotblasting machine brings the surface of the starting material to the optimum condition.

When processing steel and steel alloys, the material is mechanically descaled by a shotblasting machine before drawing. This ensures that only metallically pure material enters the drawing die of the drawing machine.

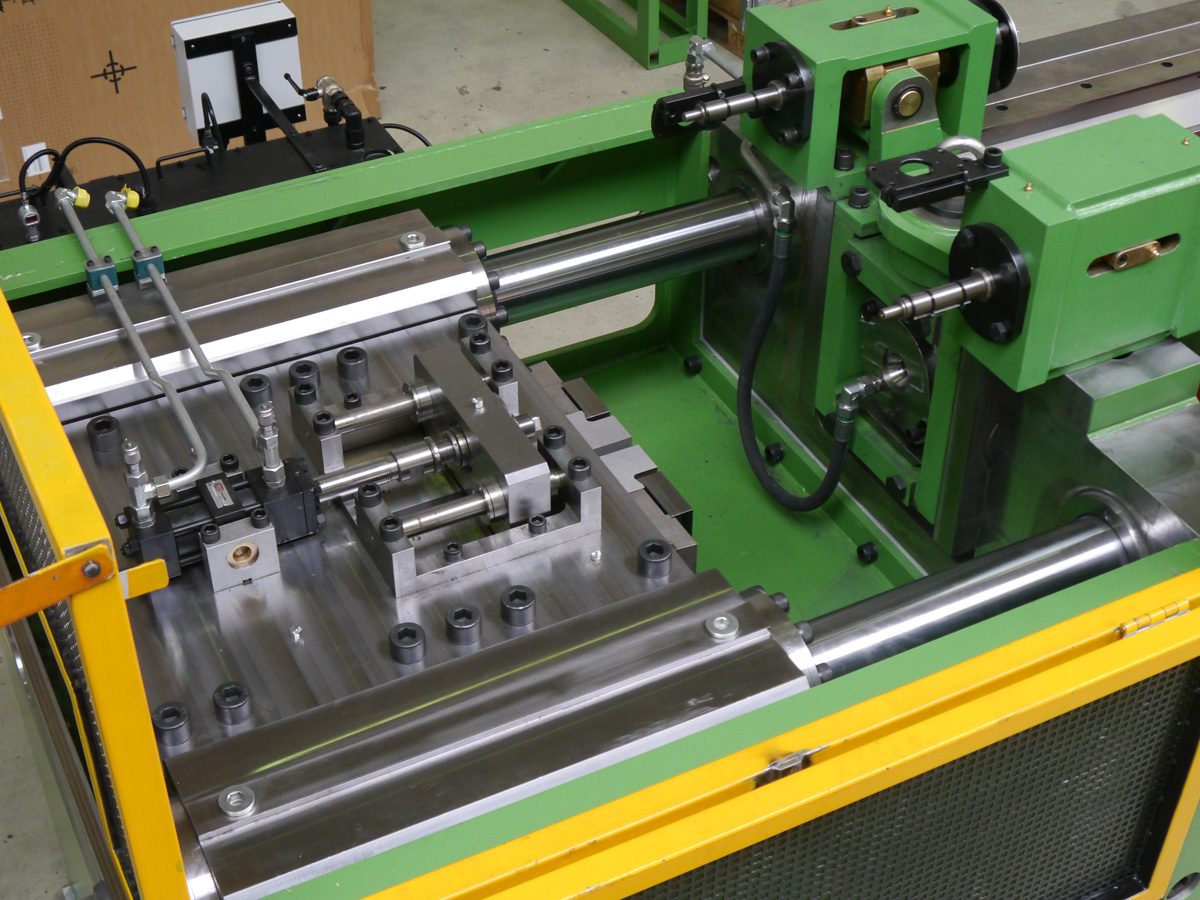

Pushpointer

The pushpointer ensures precise feeding into the drawing unit.

Depending on the material and dimensions, pushing the start of the coil directly into the die can replace the pointing process. The push-pointing force can be up to 920 kN. The simultaneous motorized adjustment of the die holder ensures optimum alignment of the drawing die. A large opening stroke prevents damage from the push-in jaws during the drawing process.

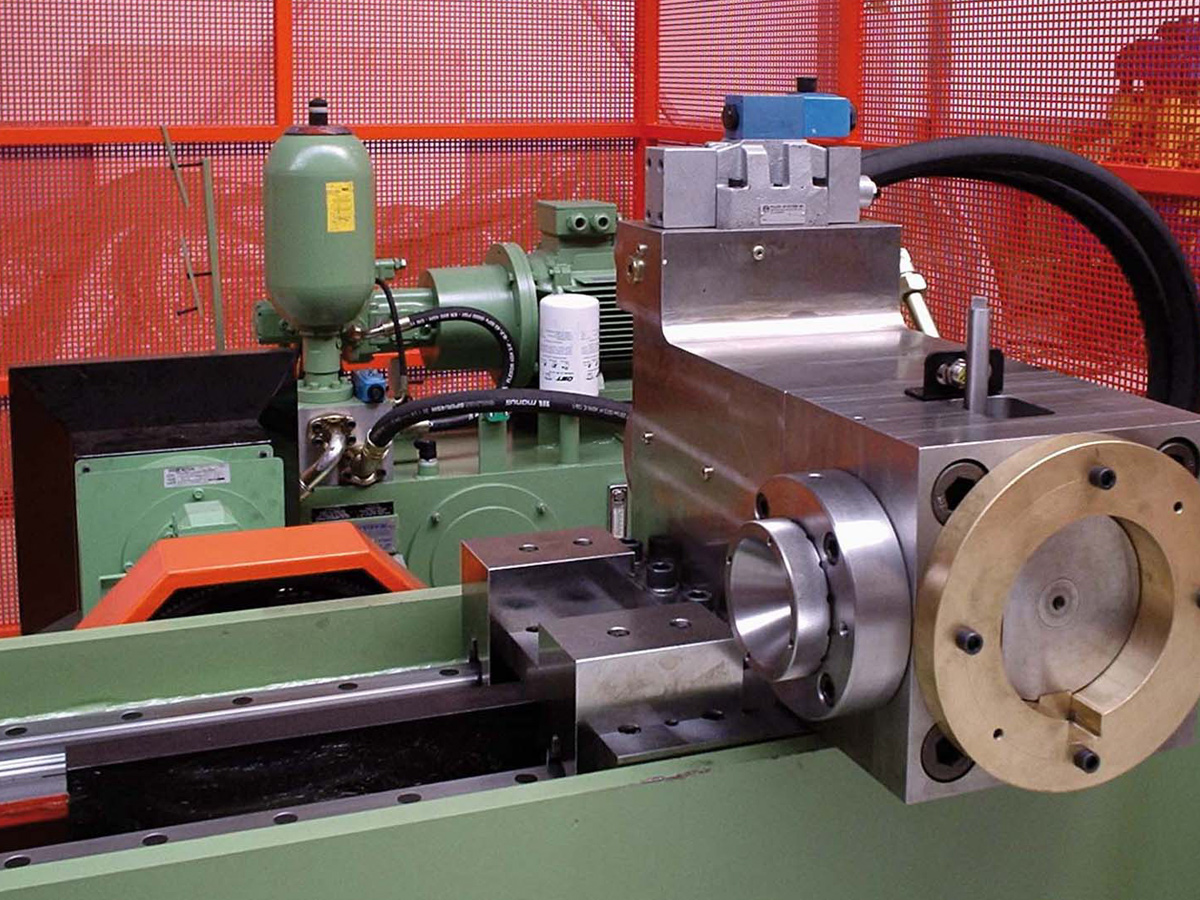

Drawing unit

The conventional drawing unit consists of two drawing carriages that are driven by cams.

This drawing process, developed by Schumag at the time, makes it possible to process material from coil-to-bar. The drawing units further developed by us are characterized by roller-guided drawing carriages, drawing cams made of forged steel, and an electronically controlled servoelectric or hydraulic drawing jaw control. Speeds of up to 150 m/min and drawing forces of up to 460 kN can be achieved.

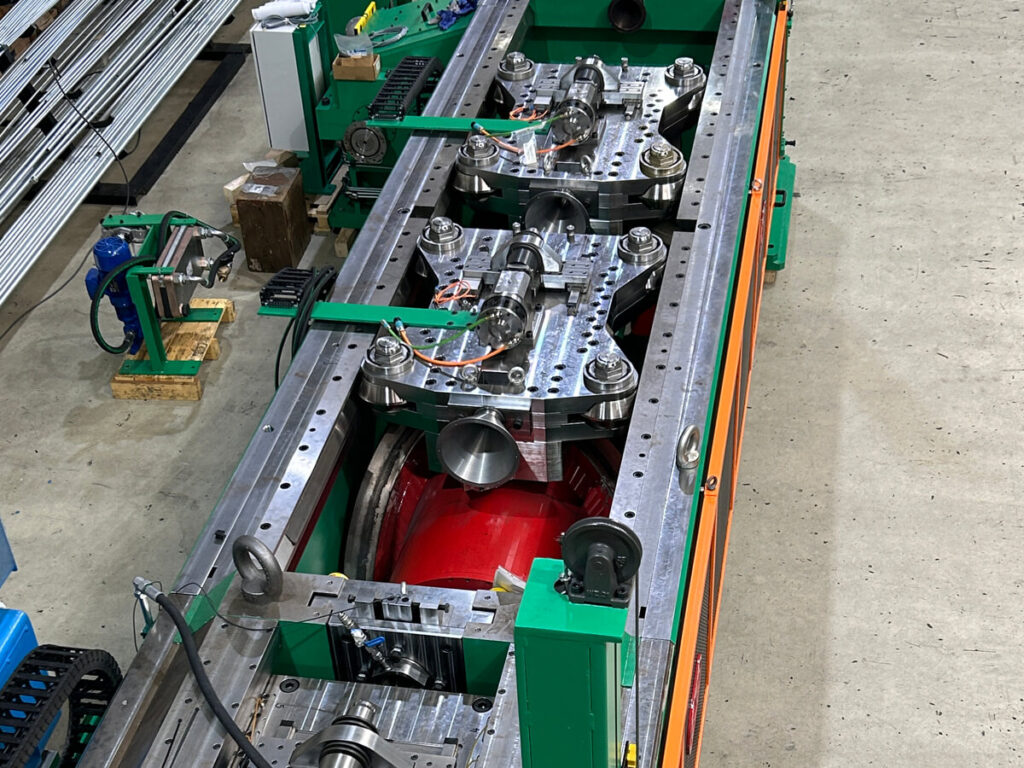

Chaintrack drawing unit

The caterpillar puller is a new generation pulling machine. It consists of two chains, which can ensure higher drawing speeds than the drawing carriage method.

Drawing speeds of up to 400 m/min can be achieved. These are particularly useful for larger batch sizes. Depending on the application, the usual speeds are between 150 and 300 m/min.

Profile straightener

The profile straightener ensures the straightening of the profile material within the drawing system in a horizontal and vertical plane.

The machine is equipped with 7 or 9 straightening rolls, which can be adjusted manually or by motor. Their position is always displayed digitally. To enable quick machine changeovers, the profile straightener has double rollers for each shaft, making it unnecessary to change the rollers.

Hydraulic impact shear

The hydraulic impact shear cuts the material on the fly with two bushings.

The electric servo drive enables precise speed control of the shear carriage. The high cutting speed and fine adjustment of the shear bushings guarantee optimum cutting surfaces. Cutting is also possible in stationary mode. A residual end control can also be used. If shear-cutting cannot be used (pipes, hollow profiles, etc.), a saw unit or a chipless cutting device is mounted on the base frame instead of the shear head.

Tube guide

The sound insulated tube guide box can be moved across manually or by motor.

It ensures close guidance of the bars to the next system unit by means of various

tube diameters. If required, the tube guide can be equipped with a side output and transport units.

2-roll straightening machine

The 2-roll straightening machine ensures precise straightness with a high surface quality.

The height-adjustable 2-roll straighteners have a fixed bottom roll and an adjustable top roll. The adjustments are carried out by motor. The adjustable components are hydraulically clamped. All parameter settings are saved via the HMI system at the customer’s request and are available when setting up the machine.

2-way delivery table

At the end of the drawing line there is a 2-way delivery table for ejecting the bars.

Depending on the use of testing equipment in the drawing line, the bars classified as defective are put out from the 2-way delivery table on the rear side. The bars found to be good are put out on the front side. The conveyor screw system ensures precise and trouble-free alignment before the bars enter the subsequent chamfering machine, other machine units or the collecting table.

Chamfering machine

The bar material often requires a certain shape of the bar end for further processing.

The chamfering machine has the task of processing the bar ends according to specifications. This includes chamfering, facing or milling the bar ends. In the non-ferrous metal sector in particular, the chamfering process is preceded by a sawing process. Depending on the bar length and diameters, the bar transport system within the chamfering machine can be designed as a chain transport or as a walking beam.

Double easy down collecting pocket

The collecting pocket ensures muted collection of the material.

The noise reduction is associated with careful collection of the final material. By using a double easy down collecting pocket, consisting of an intermediate buffer and a finished material pocket, it is possible to tie off and remove a bundle of bars during ongoing production.

Electrical control

The entire system is controlled and operated using a modern electrical control system.

Every process parameter is recorded and, if necessary, made available to the operator, the maintenance personnel and the production management. The electrical control is based on standard market components from SIEMENS or other well-known manufacturers according to customer requirements. Internet based remote control makes it possible to provide immediate assistance in the event of malfunctions. The overall control system is suitable for Industry 4.0.

Contact us - it's easy.

Your contact person

Managing Director EJP