Straightening machines

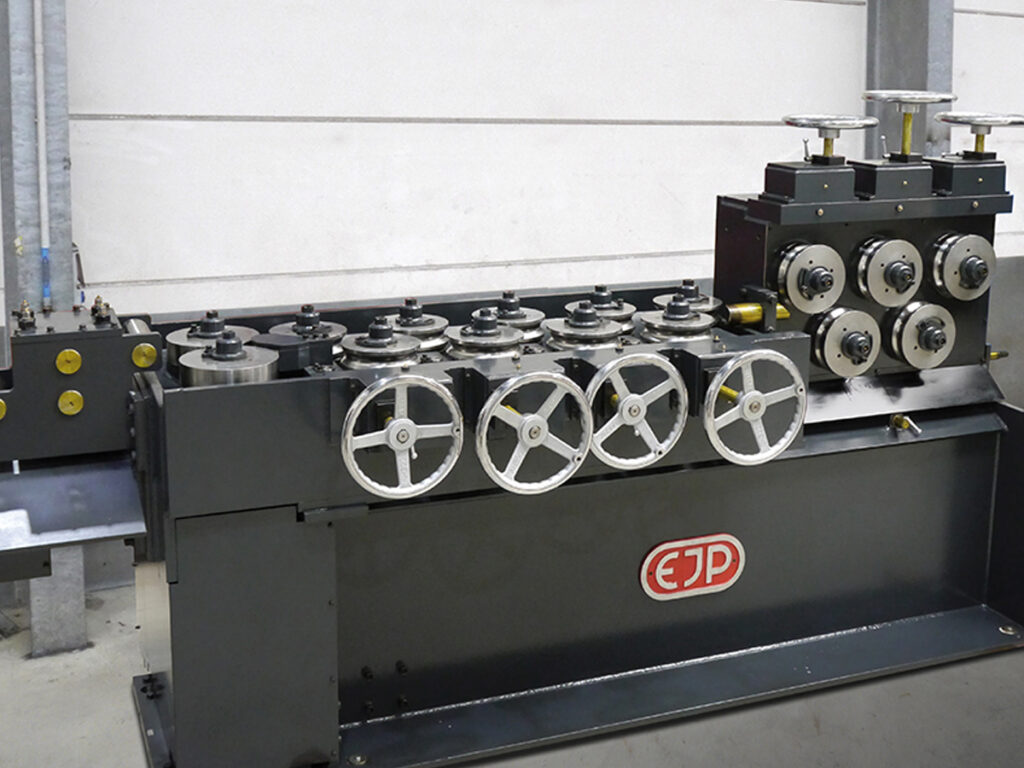

Wire straightening machine

Wire straightening machine for use in production lines.

Starting from the wire in the coil, the material is straightened horizontally and vertically so that it can be fed to another production facility.

Wire straightening machine with straightening rotor

Wire straightening machine for use in production lines.

With increased demand for product straightness, it may be useful to use a unit with a rotating straightening arbour, which precisely straightens the material.

Precision wire straightening machine

Precision wire straightening machine for use in production lines.

To achieve a high straightness of the material, a large number of straightening rolls can also be used instead of a straightening rotor. This is particularly necessary for materials that would suffer surface defects due to the rotating process of the straightening arbour.

9-roll straightening machine

Straightening machine for straightening hot-rolled or forged round bars.

Can be used as a single unit or linked in a finishing line. The bars to be straightened run through the machine in a rotating manner and are bent tens of times to achieve the desired straightness.

Automatic straightening press

Straightening machine for straightening hot-rolled, forged, drawn or peeled round bars, tubes and profiles.

For diameters larger than 250 mm, it makes economic sense to use automatic or semi-automatic straightening presses instead of roll straightening machines. Both vertical and horizontal straightening presses are available.

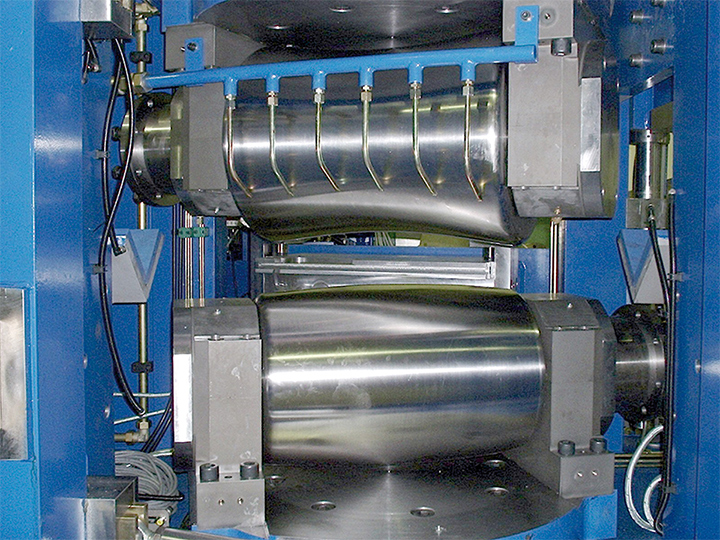

2-roll straightening machine type SP for bright material

The precision straightening machines can be used for diameters ranging from 4 mm to 250 mm.

They are used for straightening and polishing steel bars (drawn or peeled) and non-ferrous metals (cast, extruded or drawn). The 2-roll straightening machines have a fixed bottom roll and an adjustable top roll. The adjustments are carreid out by motor. The adjustable components are clamped hydraulically.

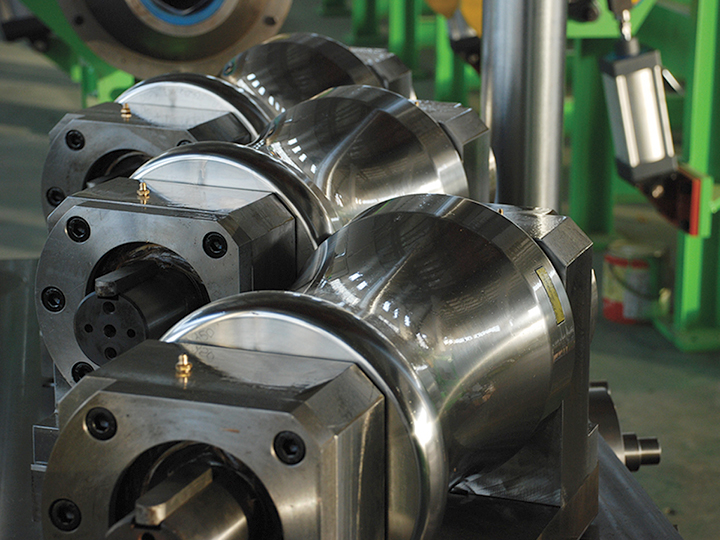

Straightening rolls for bright material and black material

Customer-specific roll contours are developed depending on the straightening task.

The specific shapes of the concave and convex rolls are calculated using unique software developed by us. The straightening rolls are made of alloyed chrome steel. They are forged from one piece, raw machined, hardened and finished or ground.

2-roll straightening machine type SP for black material

The precision straightening machines can be used for diameters ranging from 10 mm to 250 mm.

They are used for straightening steel bars (hot-rolled or forged). The 2-roll straightening machines have a fixed bottom roll and an adjustable top roll. The adjustments are carried out by motor. The adjustable components are clamped hydraulically. To compensate for the out-of-roundness of black material and the given rolling tolerances, the top roller has a hydraulic overload protection. This prevents damage to the machine. In addition, the straightening force applied can be precisely controlled and monitored.

Straightening machine for flat steel, square/hexagonal/special profiles

We have an extensive range of customized profile straightening machines for precision straightening of rolled or drawn flat steel as well as square, hexagonal or special profiles.

The number and shape of the required straightening rolls are determined depending on the straightening task. This is done using EJP software. Based on the specified number and shape of the straightening rolls, the customer-specific machine is designed and constructed using modern 3D design.

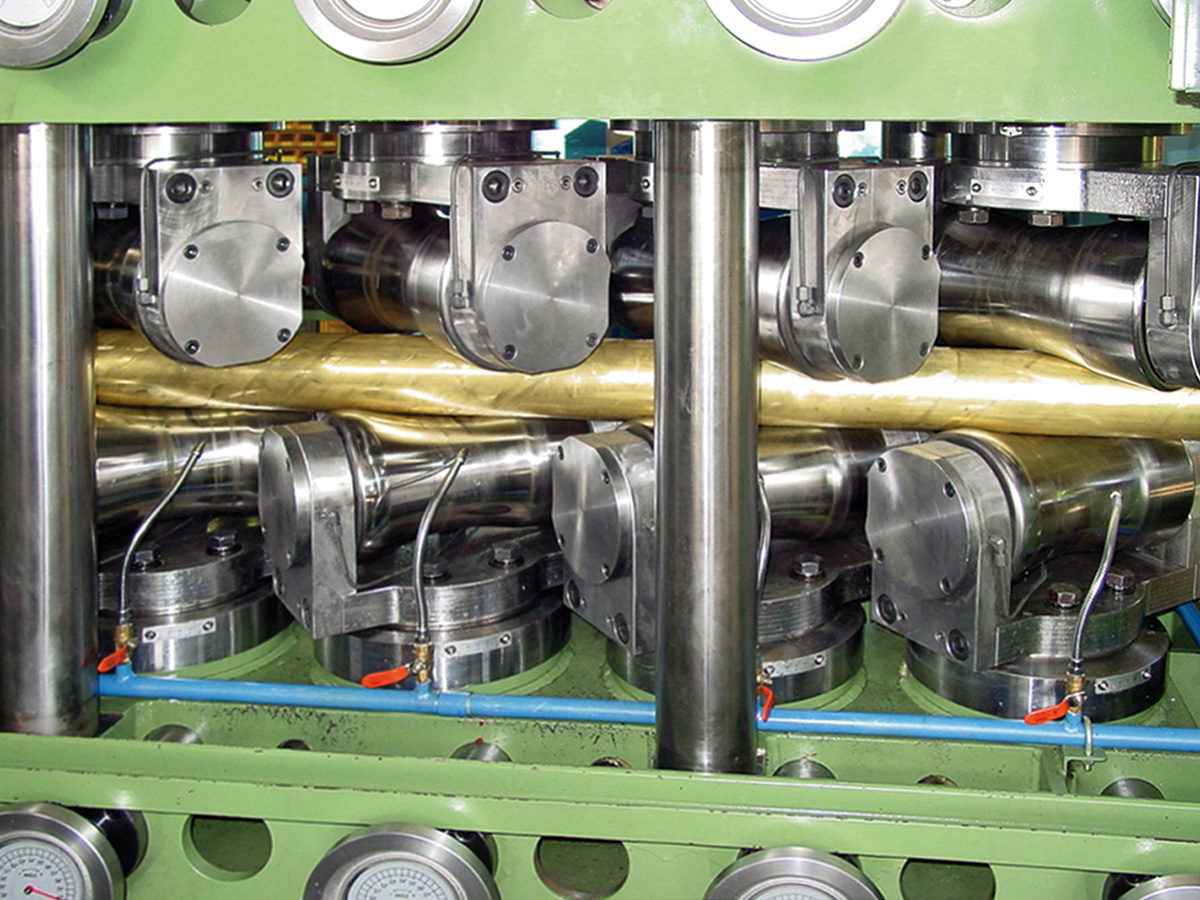

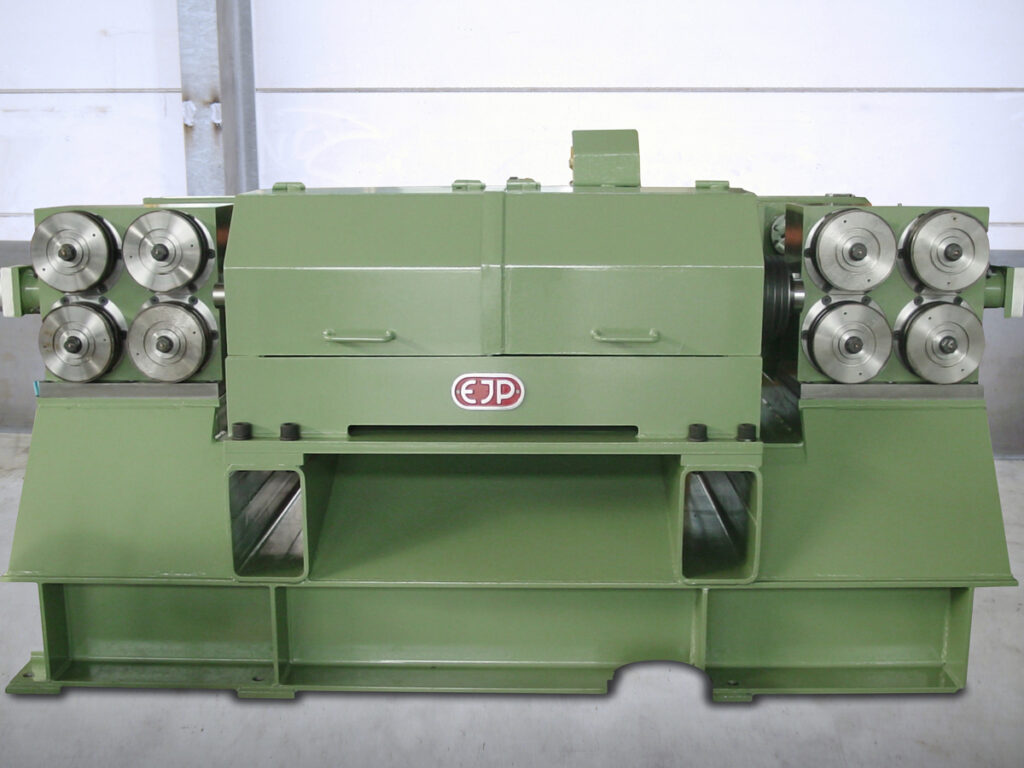

6-roll tube straightening machine

6-roll tube straightening machines are used for straightening steel and non-ferrous metal tubes with high straightness requirements.

The operator can use either precise handwheels or an automatic NC control system to set the straightening rollers. After entering the basic parameters, the control system calculates the optimum configuration for the machine. Customer-specific roll contours are developed depending on the straightening task. The specific shapes of the concave rolls are calculated using unique software developed by us. The straightening rolls are made of alloyed chrome steel. They are forged from a single piece, raw machined, hardened and finished or ground.

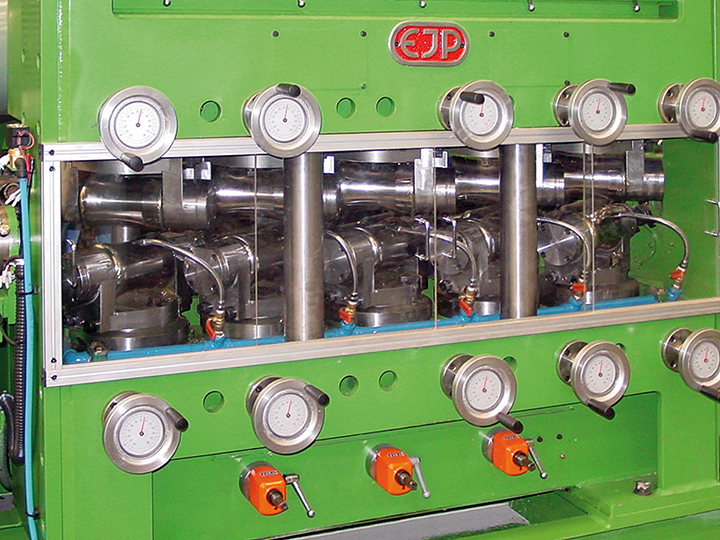

10-roll tube straightening machine

10-roll tube straightening machines are used for straightening tubes made of steel and non-ferrous metals with the highest straightness requirements.

An automatic NC control system is available to the operator for setting the straightening rolls. After entering the basic parameters, the control system calculates the optimum configuration for the machine. Customer-specific roll contours are developed depending on the straightening task. The specific shapes of the concave rollers are calculated using unique software developed by us. The straightening rollers are made of alloyed chrome steel. They are forged from a single piece, rough machined, hardened and finished or ground.

Contact us - it's easy.

Your contact person

Managing Director EJP